Have you ever wondered how the process of making soap was discovered? It is a complex chemical process that I don’t even need to learn about while I make things with my melt and pour soap. I start with a product that has been commercially produced that takes all the complexity out of it for me.

But I’m frequently asked, how is melt and pour soap different from “regular” soap? Who even figured out how to make it? In an article about the origin and history of soap I found these paragraphs:

“According to Roman legend, soap was named after Mount Sapo, an ancient site of animal sacrifices. After an animal sacrifice, rain would wash animal fat and ash, that collected under the ceremonial altars, down to the banks of the Tiber River. Women washing clothes in the river noticed that if they washed their clothes in certain parts of the river after a heavy rainfall their clothes were much cleaner. Thus, the emergence of the first soap…or at least the first use of soap.

The earliest known written soap recipe was written on clay tablets and is credited to the ancient Babylonians. A soap-like material found in clay cylinders during the excavation of Babylon…is evidence that soapmaking was known as early as 2800 B.C. Inscriptions on the cylinders indicate that fats (rendered from a slaughtered cow, sheep or goat) were boiled with wood ashes and water.”

So how about that! Up until about the 1600’s soap making rose and declined with the popularity of bathing and personal hygiene in a culture. The availability of other animal fats and vegetable oils encouraged each culture to develop their own signature soaps. like olive oil soap in Italy.

Discoveries in the early 1800’s in the process for transforming common salt (sodium chloride) into an alkali called soda ash and the chemistry behind the relationship of glycerin to fatty acids were instrumental in setting the stage for mass soap production.

Additives to basic soap recipes helped to make the final product appropriate to be melted down and poured into shapes. This final product…a melt and pour soap base…is what I use to customize with fragrance, color and plant material to make my soaps.

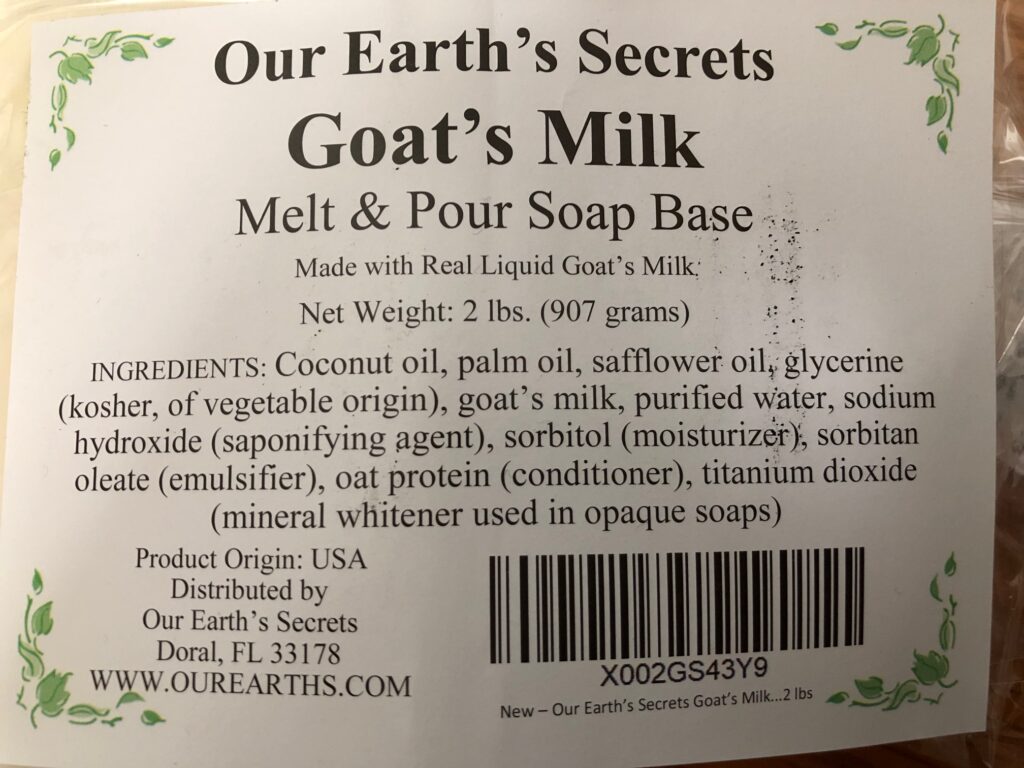

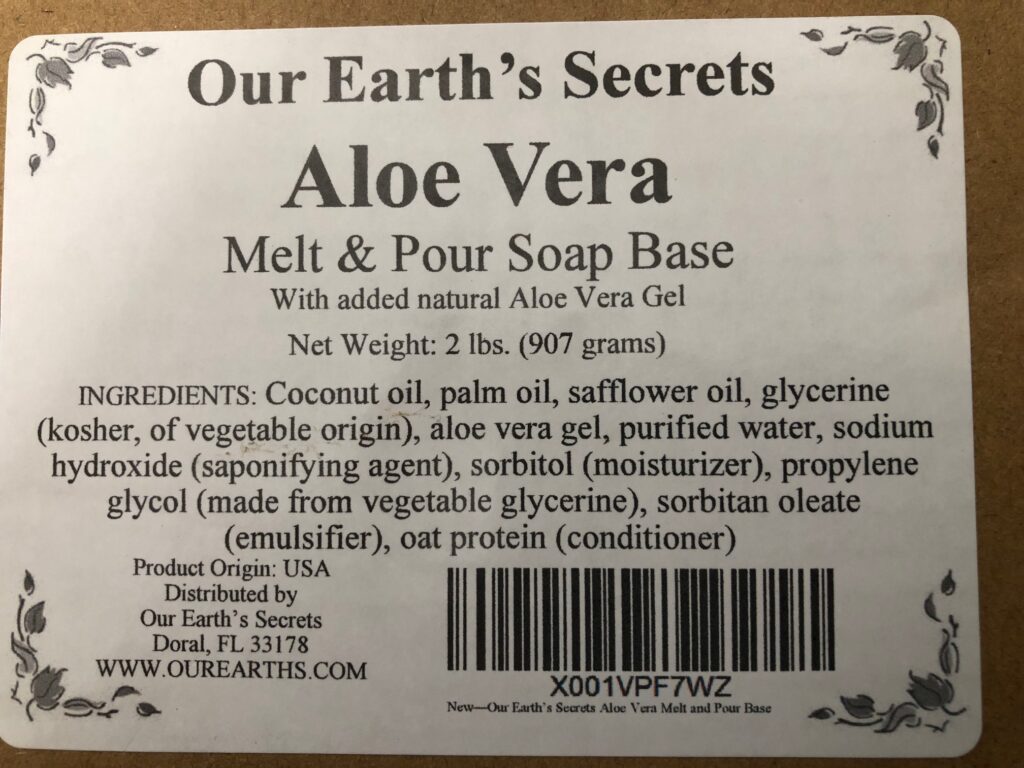

If you look at the labels of the melt and pour bases I use, you’ll see the chemical components that have been combined to make that soap.

As you can see, both of the soap bases shown above have a combination of oils, water and lye (sodium hydroxide) along with various additives (emulsifiers) that help the extra ingredients (like Aloe Vera gel and goats milk) stay mixed. The actual chemistry of working with caustic lye has been done for me.

Now when I melt the Aloe Vera soap base down, I can add additional ingredients like fragrance, color and even plant material, like Aloe Vera Gel to the soap.

I’m also learning which soap bases I like best! Apparently, soap will act differently depending on whether the water in my house is hard or soft. With our hard water, some soaps will make a nice lather, others will not. I’ve also found that I’m not happy using goats milk soap…my hands will itch after a few days. Not sure if that has anything to do with my allergy to dairy products, but I now know to avoid goats milk soap.

I’m grateful I don’t have to deal with the caustic chemical process of making soap. I also don’t have to wait 6 to 8 weeks for the soap to “cure,” which allows the crystalline structure of the soap to solidify. If you see a display of bars of soap at a craft fair with each one wrapped with just a paper sleeve and exposed to the air, you know that they were made using the hot chemical process with lye…which will continue to cure over time.

By using the melt and pour soap base, the curing time is already done. After I melt the soap down and pour it into molds, within an hour or two it is firm and ready to use.

Because melt and pour soap contains glycerin it will continue to absorb moisture from the air and could leave a white residue on the soap. That’s why I wrap each bar of soap in plastic wrap when they are done.

So, while I’m constantly trying new things with melt and pour soaps know that I’m working with real soap…it’s just the caustic chemistry I’m avoiding. Using melt and pour soap is safe for even young folks to make cute and useful gifts for themselves and others. Enjoy!

Please comment or email me directly at marykisner@comcast.net.